Choosing the right manufacturer for a wood charcoal machine is a critical decision for businesses looking to engage in sustainable charcoal production. The performance, longevity, and profitability of the entire operation heavily depend on the machinery’s quality and the manufacturer’s support services. A wood charcoal machine plays a vital role in converting wood into charcoal through pyrolysis, and therefore, selecting a reliable and efficient manufacturer is essential for optimal production efficiency.

Assessing Technological Expertise and Innovation

One of the first factors to consider when selecting a wood charcoal making machine manufacturer is the technological expertise and innovation. The technology behind the machine determines how efficiently it can convert raw wood into high-quality charcoal while minimizing environmental impact.

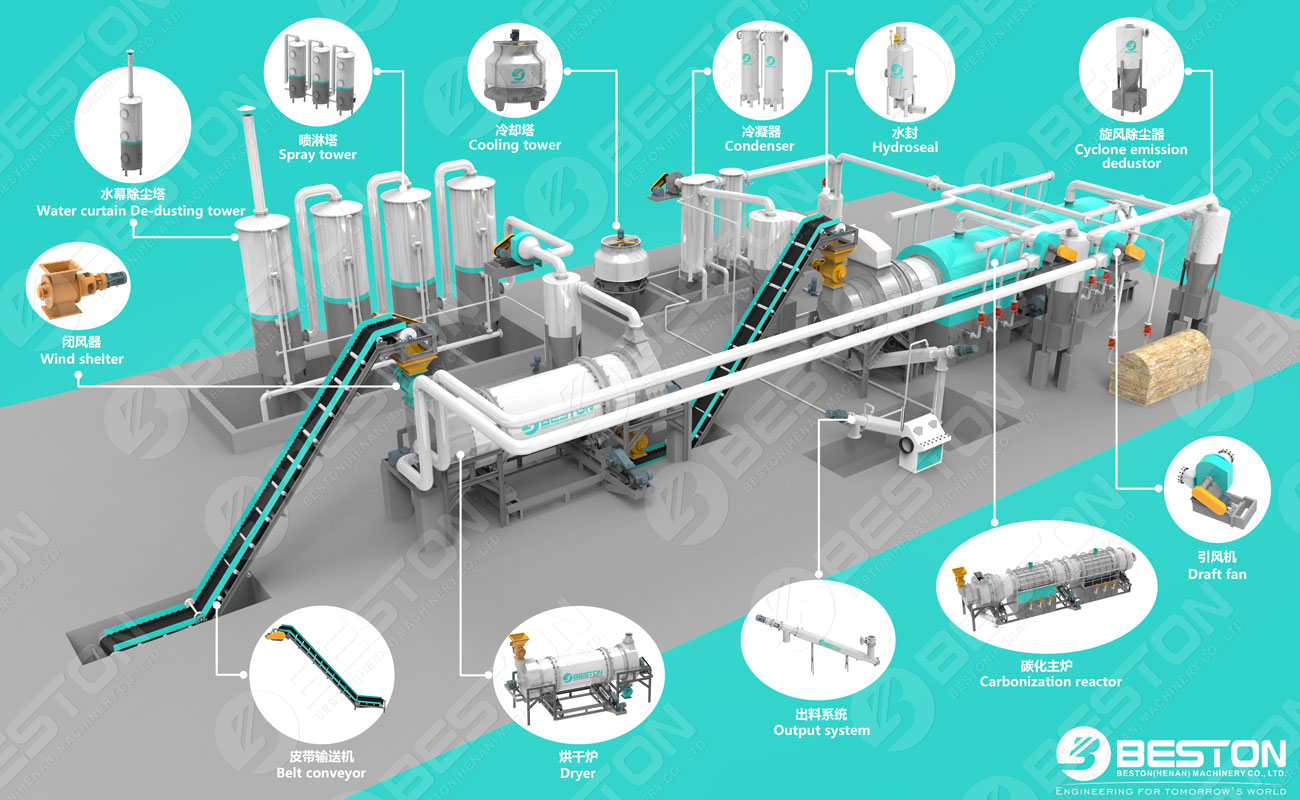

Look for manufacturers that offer state-of-the-art machines equipped with advanced features such as automatic feeding systems, temperature control mechanisms, and efficient combustion systems. These innovations can enhance productivity, reduce energy consumption, and ensure a higher-quality final product. Manufacturers who keep up with industry trends and continually invest in research and development are more likely to provide machinery that is reliable and cost-effective.

Evaluating Production Capacity and Flexibility

Understanding the production capacity and scalability of the wood to charcoal machine is crucial for ensuring that it aligns with your business goals. Different manufacturers offer machines with varying processing capacities, typically measured in terms of tons per day or per hour. A small-scale operation may not require the same level of capacity as a larger enterprise, so it is essential to choose a manufacturer that can provide machines tailored to your specific requirements.

In addition to capacity, the ability to scale up operations is also significant. As your business grows, you may need to expand your production capacity. Opt for a manufacturer that offers flexible solutions and the ability to upgrade or add components to the existing machine, such as adding more reactors or increasing automation levels. A manufacturer that can grow with your business provides long-term value.

Reliability and Durability of Equipment

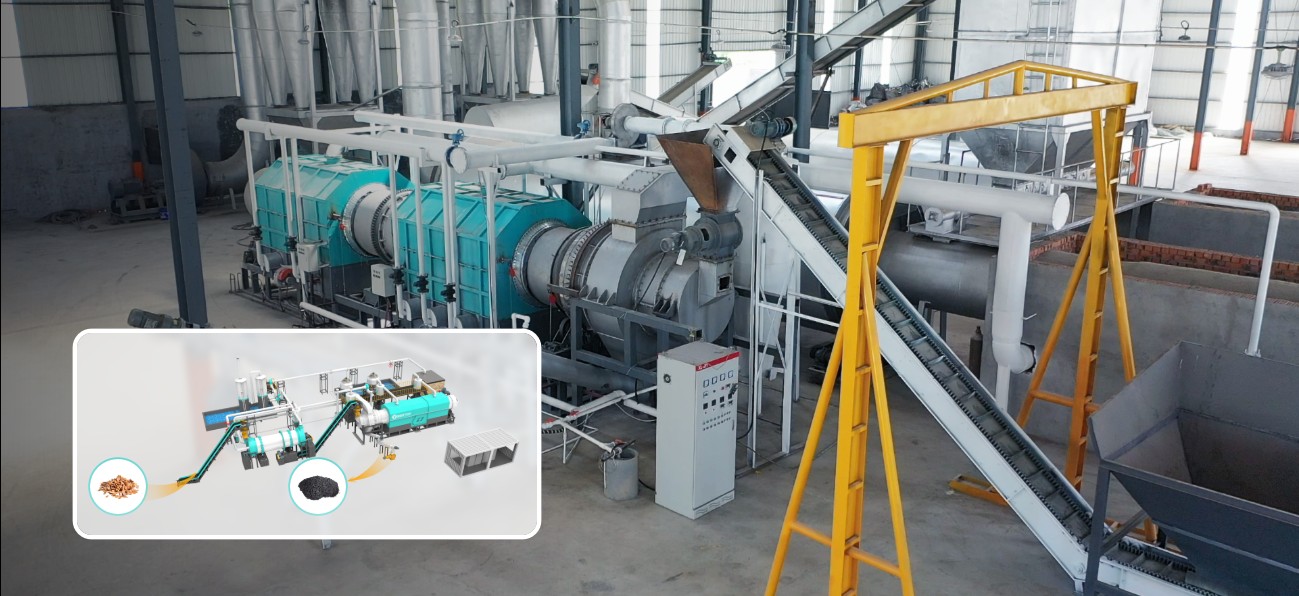

The durability and reliability of the biomass pyrolysis equipment are paramount in minimizing downtime and maintenance costs. Machines that frequently break down can lead to operational inefficiencies and lost revenue. It is advisable to select a manufacturer known for producing high-quality, durable equipment. Research customer reviews, case studies, and testimonials to gauge the long-term reliability of the machines.

Furthermore, machines that are built with high-quality materials, such as stainless steel or high-performance alloys, tend to withstand the intense heat and pressure during the pyrolysis process. A reputable manufacturer will offer products with robust construction, ensuring that the machine has a long operational life and requires minimal repairs.

After-Sales Support and Service

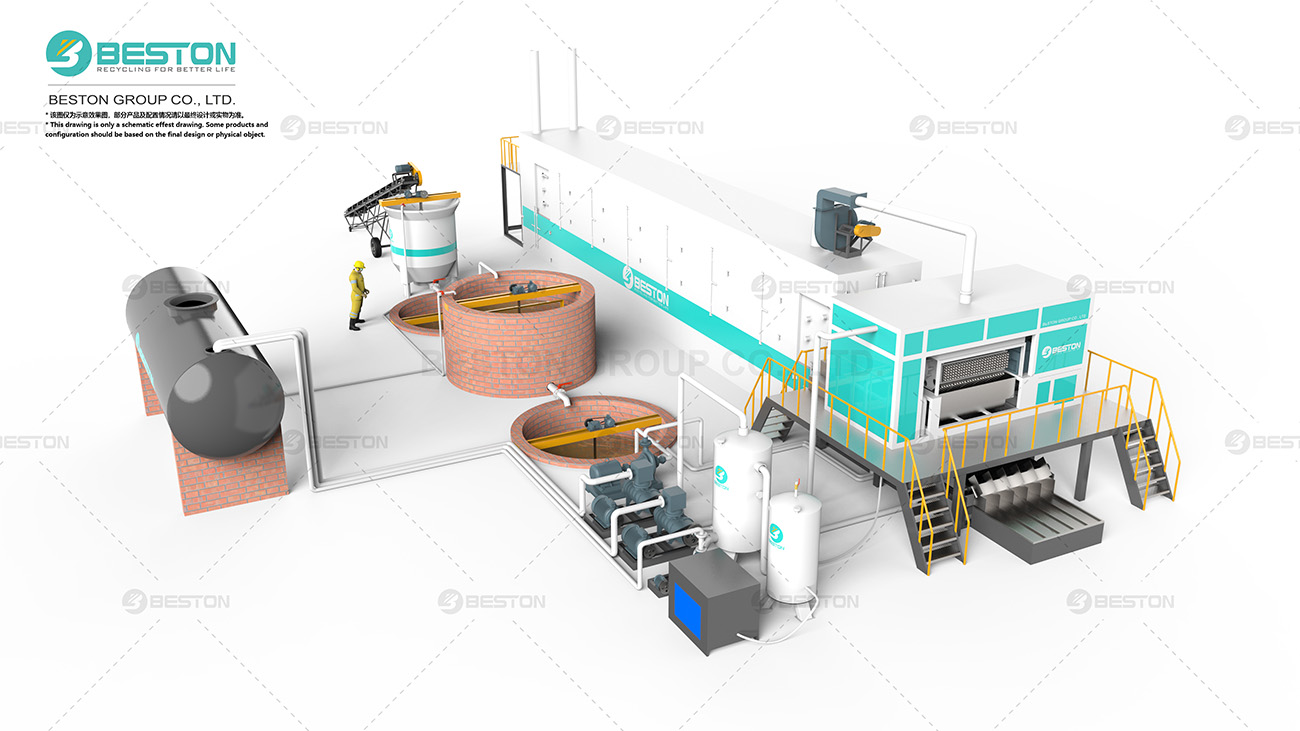

After-sales service is another important consideration when choosing a wood charcoal machine manufacturer. Manufacturing a machine is only part of the equation; the ability to receive timely and effective support post-purchase is vital to maintaining operational efficiency. A manufacturer with an established service network and a strong commitment to customer support can provide critical assistance, including installation, training, and troubleshooting. It is worth mentioning that Beston Group Co., Ltd. is famous for its excellent after-sales service.

Make sure to verify the warranty offered by the manufacturer. A comprehensive warranty that covers key components such as the reactor, feeding system, and control panels will provide peace of mind and protect against unexpected repair costs. Additionally, inquire about the availability of spare parts, as prompt access to parts will minimize downtime and prevent production delays.

Environmental Compliance and Energy Efficiency

Sustainability is a growing concern in the charcoal production industry, and selecting a manufacturer with a focus on environmentally friendly practices is essential. A good wood charcoal machine should not only produce high-quality charcoal but should also minimize harmful emissions and maximize energy efficiency.

Look for manufacturers that offer machines compliant with local and international environmental regulations. For instance, machines equipped with advanced filtration systems to capture smoke and gases can ensure that your operation remains compliant with environmental standards. Furthermore, energy-efficient models that recycle heat or use waste gases for power generation can reduce operational costs and improve the overall sustainability of your business.

Cost-Effectiveness and Return on Investment

While it is important to consider the initial cost of the wood charcoal machine, this should be evaluated alongside the machine’s long-term cost-effectiveness. A low upfront price may seem attractive, but if the machine’s performance is subpar or requires frequent maintenance, the total cost of ownership can increase substantially.

Instead, consider the machine’s overall efficiency, energy consumption, and durability when assessing the total investment. A machine that delivers higher yields, requires less maintenance, and operates with minimal energy input will provide better returns over time. Work with a manufacturer that offers transparent pricing models and clearly outlines the costs associated with installation, maintenance, and operation.

Reputation and Track Record

Finally, when selecting a wood charcoal machine manufacturer, it is essential to consider their reputation and track record in the industry. Manufacturers with a solid reputation are more likely to produce reliable, high-quality machines and provide superior customer service. Look for manufacturers with a proven history of successful installations and satisfied customers.

It is also worth considering whether the manufacturer has experience working with businesses of your scale and type. A manufacturer with a broad portfolio of clients is more likely to have the expertise needed to address your specific needs and offer customized solutions for your production requirements.