Accumulation of waste tyre is rapidly increasing leading to increased environmental pollution. This has led to the development of a new technology known as pyrolysis which is a process that coverts large chemical compounds into smaller chemical entities. This process recycles the waste tyres to produce oil and other important useful by-products. Let’s see the following article provided by Beston Henan Machinery.

Principle of Pyrolysis

The process of converting waste tyre into oil operates on the principle that at high temperatures with no oxygen, large chemical compounds are broken down into smaller chemical compounds by changing the chemical and physical components a process that is irreversible.

The composition of waste tyre that makes it suitable for recycling includes natural rubber, synthetic polymers, steel, textile, carbon black, amorphous precipitated silica, antioxidants, antiozonants, sulphur and zinc oxide. At high temperatures and low oxygen environments, these tyres can be decomposed down to produce oil, carbon black and even pyrolysis gas.

Advantages of a Waste Tyre to Oil Machine

•The use of a waste tyre to oil plant to produce oil is an environmentally friendly process since there is no smoke or bad odours produced during the process.

•Since the machine uses a hot air heating system, there is a high heating efficiency and safety performance.

•The final products are of high quality. This is achieved by pressure release during the production process.

•The process is cost effective since the raw materials required are cheap to obtain and there is no need of reducing them to smaller pieces. This is achieved by the auto tyre shredder for sale.

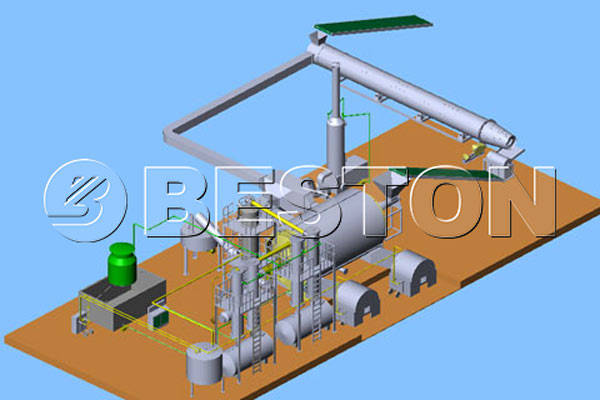

Components of a Waste Tyre to Oil Machine:

•Feeding system

•Reactor

•Transmission device

•Catalytic chamber

•Cooling tube

•A heavy tank

•A water-oil separator

•Condenser

•Light oil tank

•Safety device

•Vacuum system

•Dedusting system

•Draft fan

•Chimney

Process of Conversion of Waste Tyres to Oil

The pyrolysis process of the waste tyre pyrolysis plant for sale involves two phases whereby in the first phase the tyres are heated at high temperatures in the absence of oxygen to break down the components making up the tyres by a process known as thermal decomposition. The second phase involves cracking and post-cracking that take place at very high temperatures of between 400 degrees Celsius and 500 degrees Celsius.

Whole tyres are directed into the feeding system and the auto shredder then reduces their sizes. These are then directed into the reactor that contains a source of heat with no oxygen. In the reactor, the tyres are softened through the heating process using charcoal, wood or gas leading to the disintegration of the large molecular size tyre polymers into smaller molecular size polymers. This eventually turns into vapours and exit from the reactor into the condenser. In the condenser, the vapour is cooled to produce oil. Some of the vapour molecules are too small to be cooled and thus remain as gas which is directed back into the reactor and can then be used as fuel. The oil is then collected and the other components that are part of waste tyre are removed as a solid.

Other materials that are collected during the waste tyre to oil conversion process include;

•Carbon black that is used for strengthening in various industries such as the cement and rubber industries

•Steel wire

•Gas

Parameters to Take into Consideration During the Process

1. Heating rate

This is an important parameter during the process since it directly affects the reaction time, the amount of yield of the product, the quality of the product and the amount of energy required for the whole process. If the temperature is maintained between 400 and 500 degrees Celsius, the main product will be liquid and other hydrocarbons but if the temperature goes beyond 700 degrees Celsius, hydrogen gas and carbon monoxide gas are produced.

2. Type of feedstock

The type of products which are gas, liquid and solid highly depend on the type of feed in that whole tyres will contain most of the fibres and steel wire while shredded tyres will have more of the steel content with low fibre content. Related product: https://www.bestongroup.com/oil-sludge-pyrolysis-plant/.

3. Catalysts

In order to speed up the decomposition process, one might require a catalyst which can reduce the amount of time required to produce the products.

Applications of the oil produced during the process

The oil produced is used largely used for industrial processes including glass factories, painting factories, power plant factories, boiler factories, ceramic factories and aluminium factories.

Wanna learn more info? You can follow Beston Group on FaceBook.