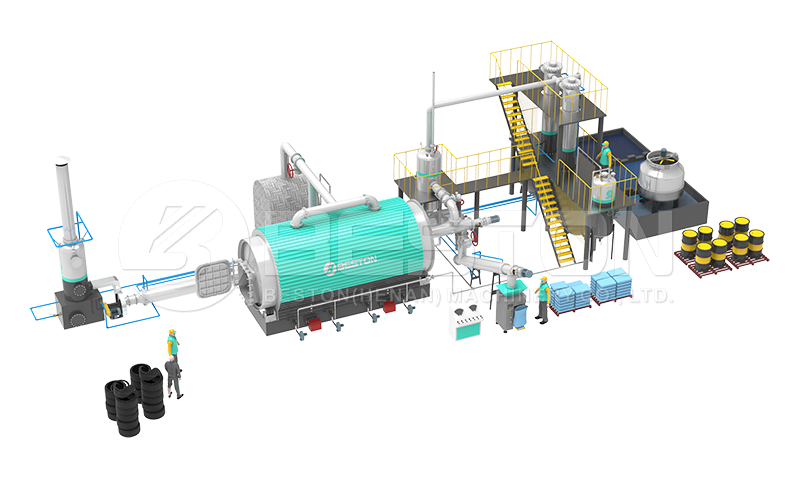

For many decades the entire planet has struggled with waste of all kinds. There is agricultural waste by the millions of pounds, plastic waste, oil sludge, rubber, tyre. We have full landfills, the ocean is full of plastic, and there is garbage blowing in the streets, we’ve got too much waste with nowhere to put it. However, there is now an emerging technology that promises to eliminate a huge portion of all of the different kinds of waste that we have been buried in for a hundred years. There is a new method called pyrolysis machine and it is environmentally friendly and can even be profitable as well. Here is a Beston tyre pyrolysis plant in South Africa.

One of the first things you’ll hear is that burning waste is toxic, and that is true. The advantage of a pyrolysis machine is that they actually bake the waste at a very high temperature, over 500 C, and that makes the waste decompose into basic ingredients without burning. The way they accomplish this is by doing the heating of the waste in a reactor chamber that has zero oxygen in it.

The fact is, as long as there is no oxygen, there can’t be any fire, and no fire means that the waste is broken down into usable, sellable, ingredients, and the emissions from the chimney are nearly clean with no smoke.

What Types Of Waste Can Be Used

This is the most fantastic part of using the pyrolysis process to eliminate waste. Nearly every type of agricultural waste, from wheat straw and corn stalks, to olive seeds and sawdust, can all be sent through a pyrolysis machine and made into profitable byproducts. In the solid waste treatment field, everything from plastics to tires and food waste to sewage sludge can all be decomposed in a pyrolysis plant. If you want more details, you can contact Beston Machinery, which is one of the top pyrolysis plant manufacturers.

What Are The End Byproducts And How Much Does A Pyrolysis Machine Cost?

The byproducts due vary somewhat based on what is fed into the pyrolysis plant. Some machines are made to handle many different types of waste while others are more specific, like only tires and plastics. This is because various wastes need different decomposition temperatures before they breakdown. And, things like tires produce large amounts of oil, while other waste makes more combustible gases instead. Still, there is a pyrolysis machine that can handle almost any kind of waste that you have. They start, for a small batch machine, it will be cheaper. However, there are large machines that are able to handle a continuous feed of waste 24 hours per day that can run into the low millions of dollars. But the cost of pyrolysis plant will be returned soon. If you want to start a waste recycling system, such as municipal solid waste sorting machine, charcoal making machine, you can contact Beston Group for more details.

If you have a waste problem, you can get a plant that is able to handle either all or most of what you have. They come in dozens of sizes, some work on batches while others are continuous feed. Stick with a high-quality manufacturer with a good reputation that has great customer service and available parts locally warehoused for best results.