The charcoal making machine for sale from a number of manufacturers offer a low-energy consuming, high-quality biochar production equipment. With the assistance of this type of machine, it is possible to convert waste materials such as coconut shells into charcoal using a high-working efficiency.

Coconut Shell Charcoal Making Process

- The coconut shells are first shredded into smaller pieces, with diameters that do not exceed 20mm.

- The conveyor then conveys the coconut shells into the quantitive-feeder whereby the shredded materials are fed into a drying host.

- Inside the drying host, the materials go through a process of flash steaming and drying to remove as much moisture as possible. From here they are passed into the carbonization furnace, directly underneath the drying-host.

- Inside the carbonization furnace, the temperature is raised which brings about a process of decomposition and biomass pyrolysis. During these processes, the shredded coconut shells are carbonized and converted into charcoal. From here the carbonized materials undergo a process of de-sulfurization and cleansing, which results in a clean charcoal product that is ready to be sold. Here is a video showing the coconut shell charcoal making process.

Features Of Coconut Shell Charcoal Making Machine

The coconut shell charcoal making machines offer a superior working efficiency at a low cost. The main features of these machines include:

Unique Structure

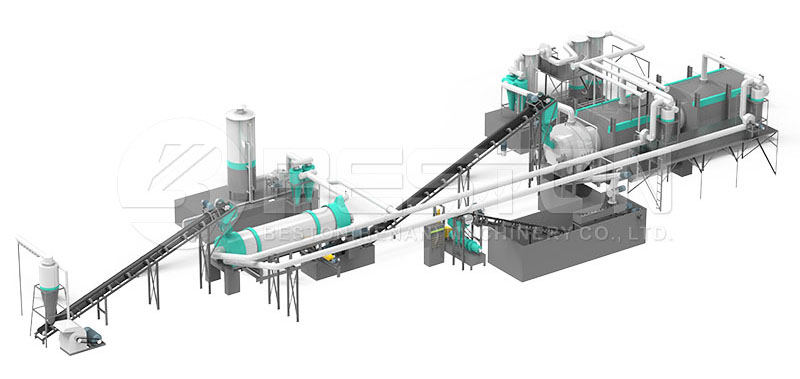

The charcoal manufacturing machine adopts a double-layer structure. The upper portion includes a drying host, while the lower portion includes the carbonization furnace. This approach helps to lower energy consumption and save space.

These machines also come with the option to include a gasifier. This feature assists with further improving the efficiency of pyrolysis and carbonization, whereby combustible gas is generated. When using the gasifier, combustible gas is sent through a cyclone dust-collector where the gas is de-dusted. From here the gas is decomposed into vinegar and wood tar. These two materials are then utilized as a fuel to heat up the furnace.

Advanced Heating Method

The coconut shell charcoal making machine employs the one fire two steps heating protocol. This works extremely well with these double-layered structures of carbonization plants. Once the carbonization furnace is heated, there is residual heat that is generated throughout the process of heating. This residual heat is then utilized as a heat source for the drying host, which means significant savings are achieved when it comes to the fuel that is used to operate this machinery.

Safe Operation

These machines feature a central control system. This separates the operators from the charcoal carbonization furnace which ensures the safety of employees that operate these machine.

There is also durable casing which protects workers from the risks of burns due to the high temperatures achieved in the furnace.

Environmentally-Friendly

Beston charcoal making machine that uses biomass as a source is regarded as a green waste recycling plant which poses no risks of producing pollution. These machines use a sealed discharging and feeding features so that no pollution is released into the environment. The combustible gas generated in the machine undergoes a process of desulfurization which means no harmful gases are released into the atmosphere.