The pyrolysis plant takes waste rubber, plastic and tires and turns them into oil. This plant is a great investment to bring you money while reducing waste. The oil that the machine produces can be sold and it also is easy to process the oil down further so it can be turned into gasoline. Read on to learn how to find the best pyrolysis plant for sale.

When you are looking for a pyrolysis plant you need to take your budget into account first. It is important that you know what your budget is when you start looking for these machines. You have a lot of choices when you are looking for pyrolysis machines and it will be easy to choose the machine you want once you know what your budget is.

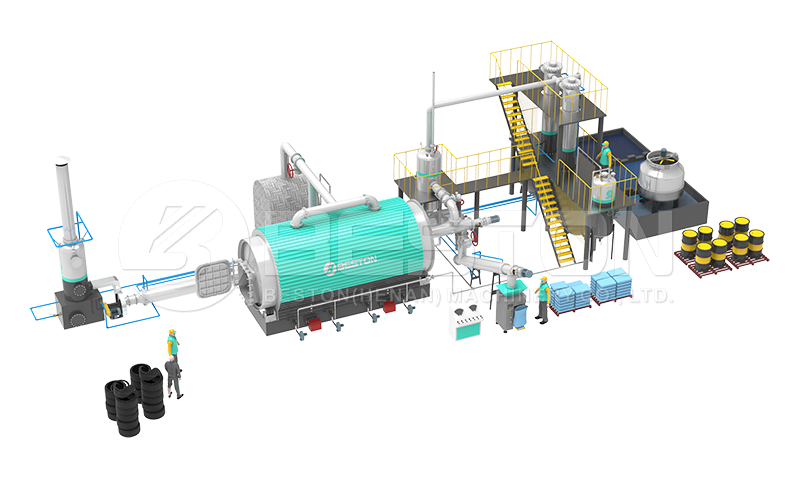

Moreover, tire recycling gives your business many benefits if you use a great quality machine. Beston pyrolysis machine is high-quality and it is made with the best materials. So the service life can reach up to 5 to 8 years. The machine is also designed to reduce pollution. The machine is equipped with the latest cleaning devices that will ensure that the machine meets emission standards. Besides, you can use the machine without having to worry about safety issues when you are using it. Here is a link for you to learn how to start a profitable tire recycling business: https://bestonasia.com/tire-recycling-business-profit/.

The machine doesn’t take a long time to produce and it is also very high quality which ensures you get the best results each time you use it. The machine also has a short delivery time which means you won’t be waiting a long time for your machine to arrive. The plant can be exported to any country and the pricing on the machine is very affordable which means you can easily find the machine that you want for sale.

Make sure that you work with a manufacturer that offers a quality after-sales service. The manufacturer should go the extra mile to ensure that you are satisfied. You want to make sure that training, installing, and adjusting the continuous pyrolysis machine are all included with the price.

The manufacturer will send out a team of professionals to help you deal with all of your needs and they will ensure that you get the most out of your machine. Your entire team will know how to run the machine efficiently and it won’t take a long time to figure out how to get the machine up and running. This machine is a great investment in your business and it can help you in so many ways.

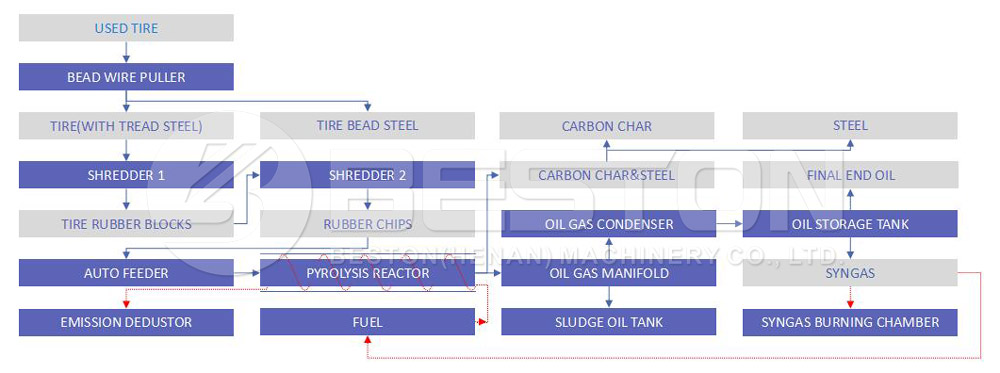

This pyrolysis machine is safe to set up and use and it is very easy to use. When your employees know how to operate the machine you can quickly set things up so you are ready to produce large amounts of oil. Fuel oil is the most commonly produced oil with this machine. The machine can also be used to produce carbon black. You can contact Beston China Group for more details.