Operational Efficiency of Fully Automatic Pulp Molding Machines

Automation and Production Capacity

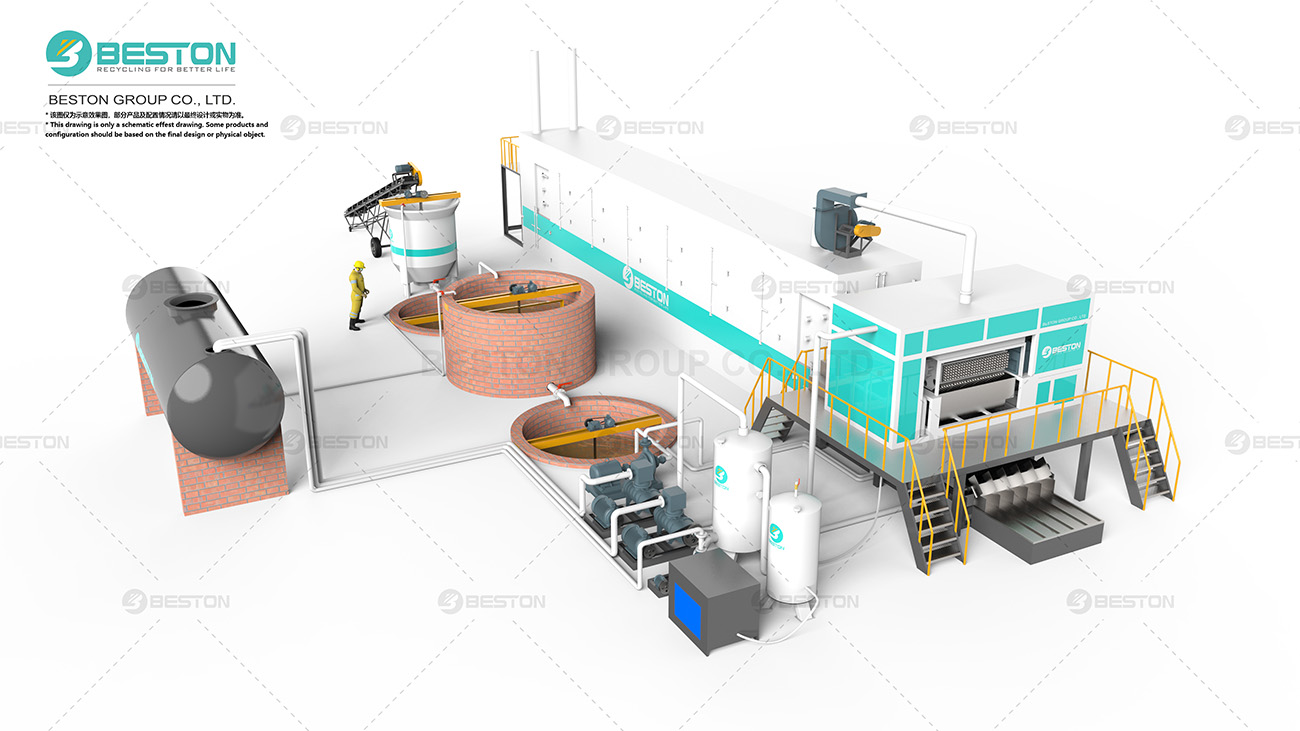

A fully automatic egg tray making machine is designed to maximize production efficiency and consistency. Unlike semi-automatic or manual systems, which require substantial human intervention, these machines automate the entire production process, from pulp preparation to egg tray forming. The automation encompasses:

- Pulp Preparation: The machine integrates systems for mixing and preparing pulp, ensuring uniform consistency and optimal molding quality.

- Molding and Shaping: The fully automatic system uses precise molds and high-pressure forming techniques to produce egg trays with consistent dimensions and structural integrity.

- Drying and Packaging: Automated drying units expedite the drying process, reducing the time required for egg tray formation and allowing for seamless transition to packaging.

The high production capacity of these machines is particularly advantageous for large-scale operations, enabling continuous production without significant downtime.

Quality Control and Precision

Precision engineering is a hallmark of fully automatic pulp molding machines. Advanced control systems monitor and adjust various parameters throughout the production cycle, including pulp density, molding pressure, and drying temperature. This level of precision ensures that each egg tray meets stringent quality standards, reducing the likelihood of defects and ensuring uniformity across batches.

Technological Innovations in Pulp Molding Machines

Advanced Control Systems

Modern fully automatic pulp molding machines are equipped with sophisticated control systems that enhance operational efficiency. These systems include:

- Programmable Logic Controllers (PLCs): PLCs manage the machine’s operations, allowing for real-time adjustments and optimizations based on production needs.

- Human-Machine Interface (HMI): The HMI provides operators with a user-friendly interface for monitoring machine status, adjusting settings, and troubleshooting issues.

These technological advancements facilitate seamless operation and contribute to the overall efficiency of the production process. To learn more about advanced technologies, please contact Beston.

Energy Efficiency

Energy consumption is a critical consideration in the design of fully automatic paper pulp molding machine. Many modern systems incorporate energy-efficient technologies, such as:

- Heat Recovery Systems: These systems capture and reuse heat from the drying process, reducing overall energy consumption.

- Variable Frequency Drives (VFDs): VFDs regulate motor speeds to match production requirements, optimizing energy use and minimizing waste.

These innovations contribute to lower operational costs and a reduced environmental footprint.

Integration of Environmental Technologies

The integration of environmental technologies into fully automatic pulp molding machines reflects a commitment to sustainability. Key environmental features include:

- Waste Management Systems: These systems recycle excess pulp and water, minimizing waste and reducing the need for raw material inputs.

- Biodegradable Pulp: Many machines utilize biodegradable pulp materials, further enhancing the environmental benefits of the production process.

These features not only improve the environmental performance of the production process but also align with global sustainability goals.

Environmental Benefits of Fully Automatic Pulp Molding Machines

Reduction of Plastic Waste

One of the most significant environmental benefits of using paper pulp molding machines is the reduction of plastic waste. Traditional egg trays are often made from plastic, which poses environmental challenges due to its non-biodegradable nature. By contrast, paper pulp egg trays are made from recycled paper, which is biodegradable and environmentally friendly. The shift to pulp molding technology helps mitigate the impact of plastic waste and supports efforts to reduce landfill accumulation.

Sustainable Resource Utilization

Fully automatic pulp molding machines contribute to the sustainable utilization of resources by recycling paper and cardboard waste. The process involves:

- Paper Recycling: The use of recycled paper and cardboard as raw materials reduces the need for virgin resources and minimizes deforestation.

- Water Recycling: The incorporation of water recycling systems ensures that water used in the production process is reused, reducing overall water consumption.

These practices align with principles of circular economy and sustainability, promoting responsible resource management.

Energy Conservation

Energy conservation is a crucial aspect of sustainable production. Fully automatic pulp molding machines enhance energy efficiency through:

- Optimized Drying Processes: Advanced drying technologies reduce energy consumption by improving drying efficiency and minimizing heat loss.

- Energy-Efficient Components: The use of energy-efficient motors and drives further contributes to reduced energy usage.

By optimizing energy consumption, these machines lower operational costs and support environmental conservation efforts.

Market Trends and Future Outlook

Growing Demand for Eco-Friendly Packaging

The increasing awareness of environmental issues and the shift towards sustainable practices are driving demand for eco-friendly packaging solutions. Fully automatic egg crate making machine is well-positioned to meet this demand, offering a scalable and efficient solution for producing biodegradable egg trays and other packaging materials.

Technological Advancements

Ongoing research and development in pulp molding technology are expected to yield further advancements, including:

- Enhanced Automation: Future machines may incorporate even more advanced automation features, further reducing the need for manual intervention.

- Improved Materials: Innovations in pulp material composition and molding techniques could lead to enhanced product performance and sustainability.

These advancements will likely continue to drive the growth and adoption of fully automatic pulp molding machines in various industries.\

Conclusion

Fully automatic paper pulp molding machines play a crucial role in the efficient production of egg trays and other eco-friendly packaging solutions. Their advanced automation, technological innovations, and environmental benefits make them a preferred choice for modern production facilities. By enabling efficient and sustainable production processes, these machines contribute to reducing plastic waste, conserving resources, and promoting environmental stewardship. As the demand for sustainable packaging solutions grows, fully automatic pulp molding machines will remain at the forefront of the industry, driving progress and innovation in eco-friendly manufacturing.