If you are looking for ways to increase your business profitability, then you may want to consider investing in a wood charcoal making machine. Here are four reasons why this may be a wise decision:

1) Increased Demand for Charcoal Worldwide Due to Its Many Benefits

The charcoal making industry is booming due to the increased demand for charcoal worldwide. Charcoal has many benefits, including being an excellent fuel for barbecues, grills, and other cooking applications. It is also a popular choice for artists and crafters due to its high heat retention and easy ignition. In addition, charcoal is a valuable soil amendment that can help improve plant growth. As a result, there is a growing market for wood charcoal, making it an excellent investment for those looking to enter the charcoal making industry.

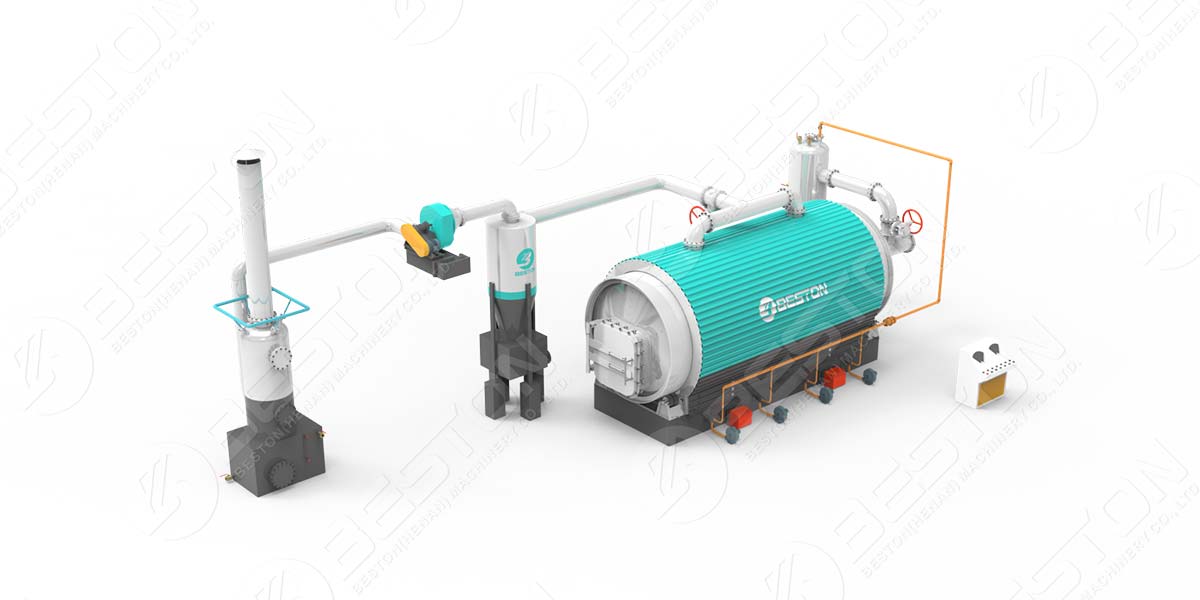

A wood charcoal making machine is the perfect way to produce high-quality charcoal in large quantities. With a wood charcoal making machine, you can be sure that you are producing a product that will be in high demand worldwide.

2) Low Cost and Easy Operation of The Machine

The machine produces high-quality charcoal that can be used for cooking, grilling, or even making art. Best of all, the machine is relatively low cost and easy to operate. Charcoal made from hardwood trees is especially effective at absorbing and retaining heat, making it ideal for use in stoves and fireplaces. In addition, wood charcoal is also a great source of fuel for grilling. When used in conjunction with a grill brush, it can help to create beautiful char marks on meats and vegetables. As an added bonus, the charcoal produced by the charcoal production machine can also be used as garden fertilizer. Wood charcoal is rich in minerals and helps to improve soil health, making it an excellent choice for those who want to invest in a sustainable gardening practice.

3) Versatility of Using Different Types of Wood To Create the Charcoal

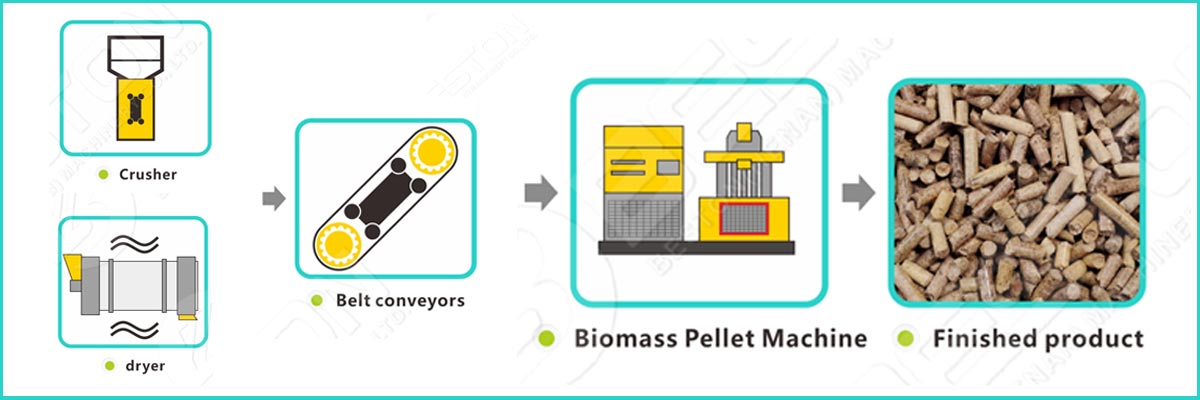

Any business owner knows that in order to be successful, you need to be able to adapt to change. The same can be said for those who are in the business of manufacturing charcoal. A wood biochar production equipment gives you the ability to do just that – to experiment with different types of wood and see which one produces the best results. Not only does this allow you to find the perfect type of wood for your needs, but it also allows you to save money on your raw materials.

In addition, a wood charcoal making machine is also a great way to diversify your product line and appeal to a wider range of customers. By offering a variety of charcoal products, you can make sure that there is something for everyone. So if you’re looking for a versatile and affordable way to produce charcoal, then a wood charcoal making machine is the perfect investment for your business.

4) High Return On Investment Potential

When it comes to generating profits, there are few investment opportunities that offer the potential for high returns like a wood charcoal making machine. Not only can you generate income from the sale of the finished product, but you can also save money on your own fuel costs. A wood charcoal making machine can be used to produce a variety of other products, including activated carbon and biochar. As a result, investing in a sawdust charcoal making machine is a smart financial decision that can pay off handsomely in the long run.