Most industries have recently invested widely in the tire recycling business since maximum profit is guaranteed. This is a market niche that should be addressed promptly if you have a constant supply of old and used tires. It can be a sure way to earn you your daily income with the tire recycling plant.

Reasons To Invest In A Waste Tire Recycling Plant

The first and obvious one is to protect and take care of the environment. The rubber used to manufacture tires is not able to decompose get and absorbed to the environment easily. It could take several years for the tire to get fully decomposed. Instead of letting these tire products cause harm to you and your surroundings you can easily start a business and generate some income from the recycling business. Averagely more than a quarter a million tires are disposed yearly and for sure this creates a strong base for raw materials for your business. In addition to that, tire products are often beautiful e.g chairs, swings, etc.

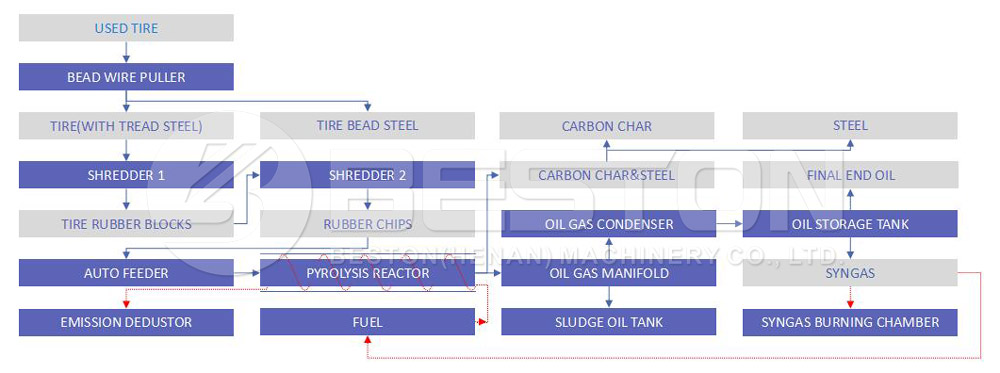

Let’s now focus on how to go about recycling the tires. One of the common tire recycling plants is the pyrolysis plant. This decomposes the tires at a very high temperature after which the result expected is tar, carbon black and of course the steel wire. The whole process involves cutting the tires into small sizes then exposing them to high temperatures where they melt and convert to your desired product. It is also important to note that the equipment, tools and process highly influence the result. These end products are quite useful in many uncountable aspects. Click here to know more about small pyrolysis machine.

Moving to the other product, steel. Steel can be used in various ways. For in stance, hard steel is used to make trolleys mostly in your local supermarket. Amongst commercial uses. Carbon black the other end product you collect after the recycling process, carbon black is commonly used to reinforce fillers in tire company the same goes for all other rubber products. Also, you need to consider the tyre to oil plant price. Pick one with reasonable price.

Lastly, we focus on the requirements that you need to have to enable you to start a waste tire recycling business.

Land is the number one requirement. You need to have enough land to build the facility and working environment for the staff and engineers running the plant.

Documentation: You need to have the right papers from the authority to run your business. You need to obtain a license from both the local authorities and as well as from the environmental ministry or department. Seek out a reliable pyrolysis plant manufacturer.