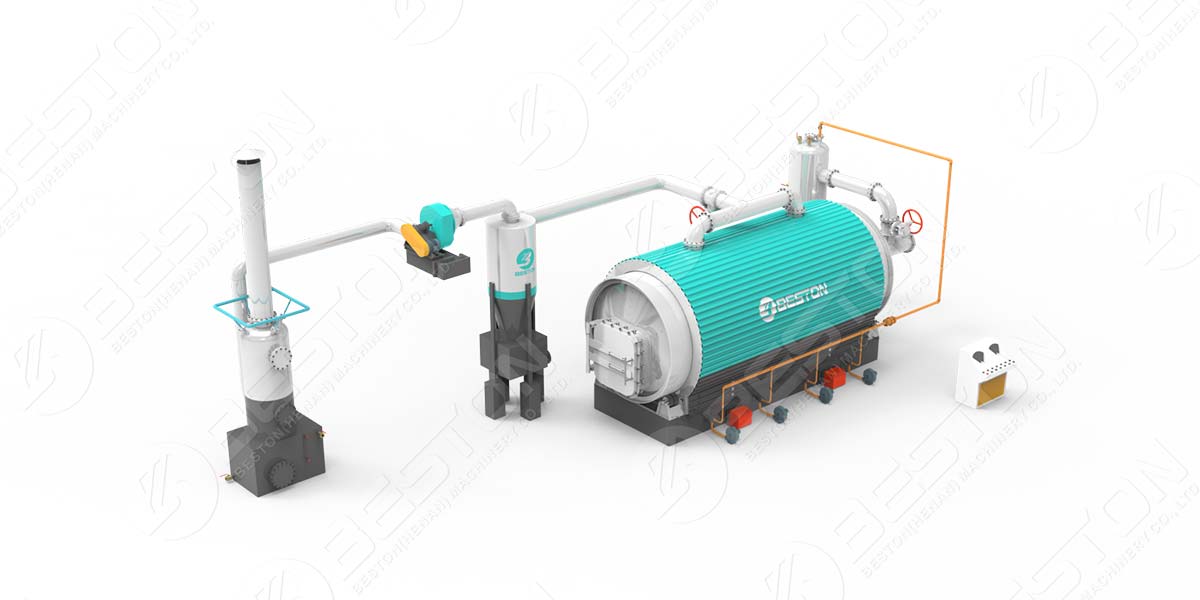

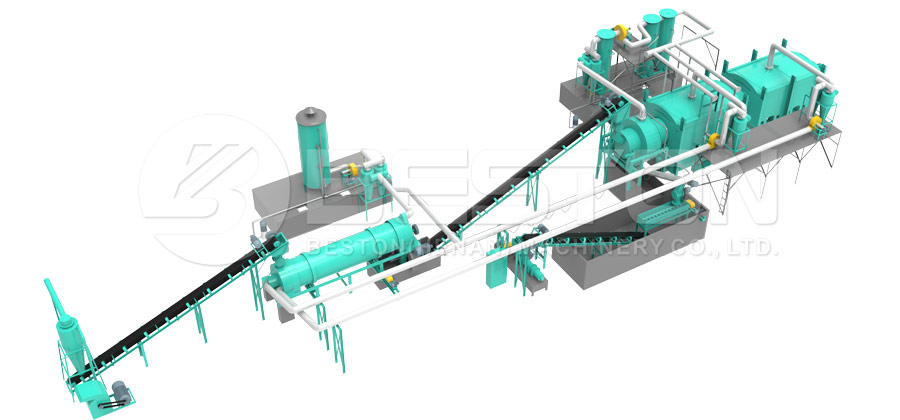

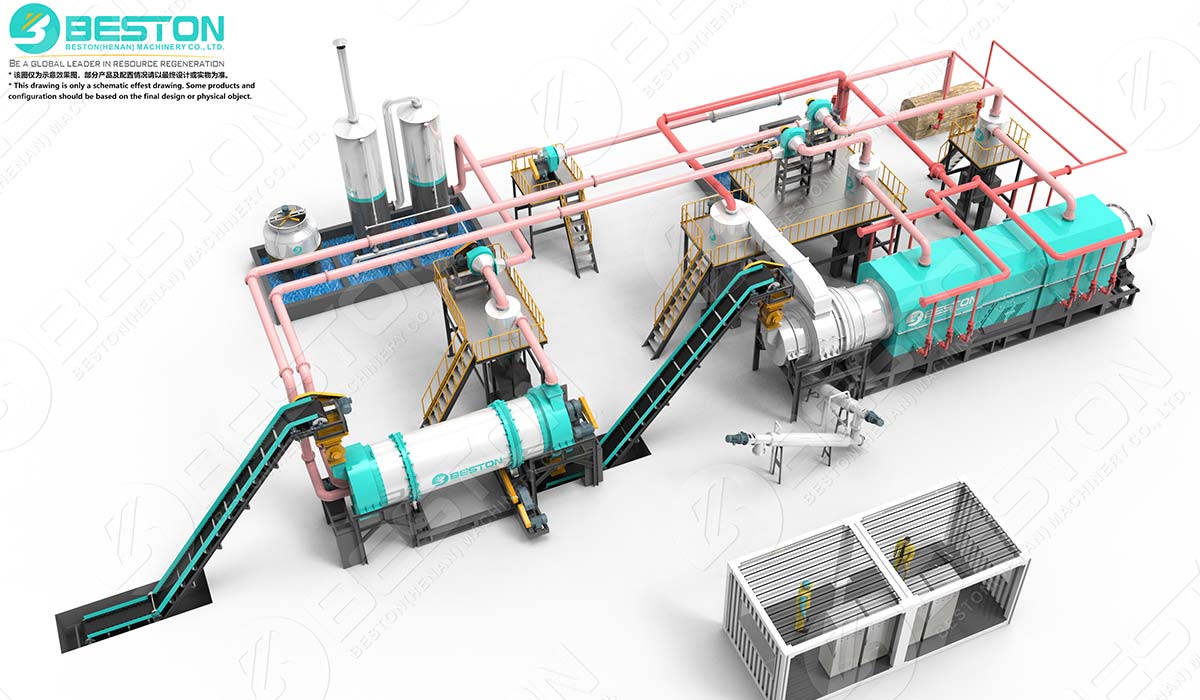

One of the best ways to get rid of waste bamboo is to use the bamboo charcoal making machine. This machine allows you to take waste bamboo and turn it into charcoal. The machine will also take other types of biomass like sawdust, wood, rice husk, coconut shell and more. The machine is affordable and it is also easy to use so you can start making money with it fast.

Charcoal is used for a variety of purposes. It can be used for heating and cooking. Charcoal is also used to make incense and it is a common ingredient in fertilizer and other products. Charcoal is very easy to sell and you can often sell it for a great price and make your money back faster on the bamboo charcoal making machine.

The biochar machine is also good for the environment since it takes waste and turns it into something you can sell. The machine is very easy to use and it is packed with eco-friendly additions that stop pollution and ensure that no dust gets out into the environment.

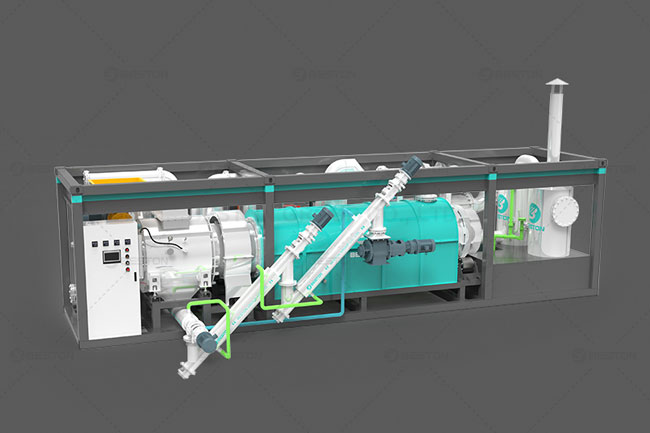

The machine is also equipped with all of the latest safety devices and it is easy and economical to use. It won’t use a lot of energy and the machine makes it easy to save power whenever you use it. This charcoal machine is a great investment in your business and it will help you make a lot of money.

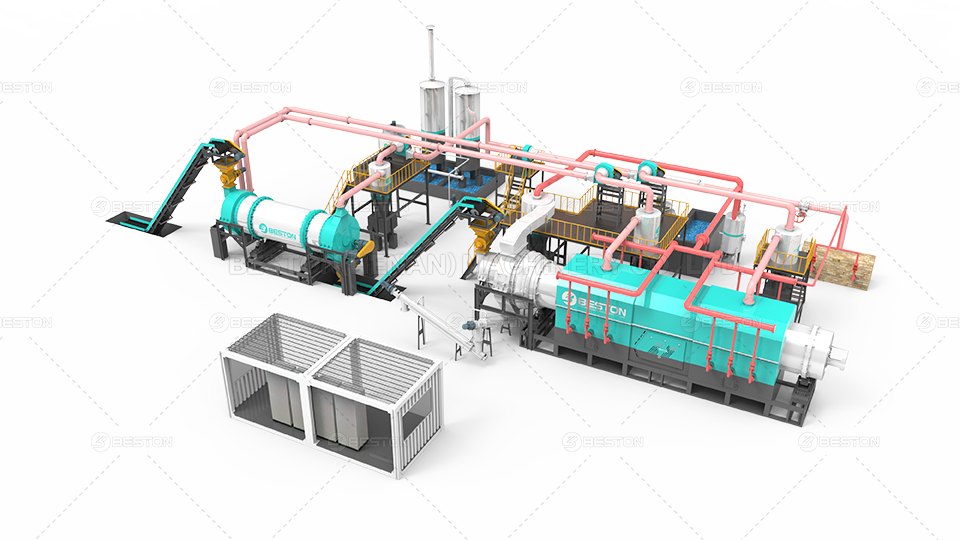

The machine is affordable and can be exported to many different countries. The price of the machine is affordable and the price depends on how big the machine is and how much charcoal you want to process. The price will go up as the capacity goes up so think about how much charcoal you want to make before you choose the biochar machine.

You have a lot of options with these machines and it will be easy to choose a machine that is the right fit for your business. The price is affordable and it’s easy to ship the machine wherever you need it to go.

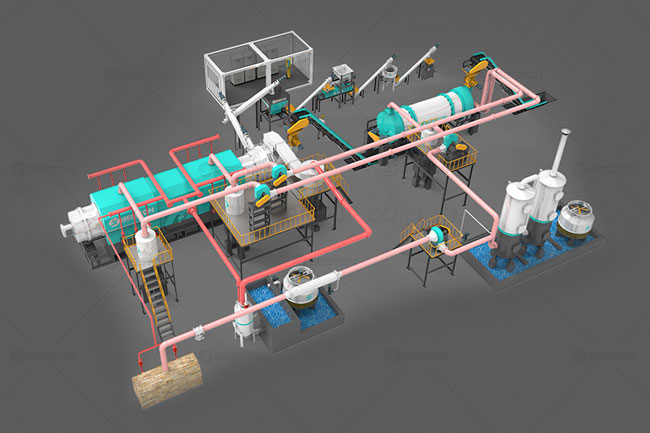

This plant can take a lot of bamboo out of the environment and turn it into something useful. Every machine goes through a long testing process before it is released for sale. All of the parts are high quality and the machine is designed to need minimal maintenance.

Making charcoal is easy when you use a charcoal making plant. The mobile biochar machine will help you produce tons of charcoal with ease and you can sell the charcoal for a great price. This plant is perfect for any recycling business.