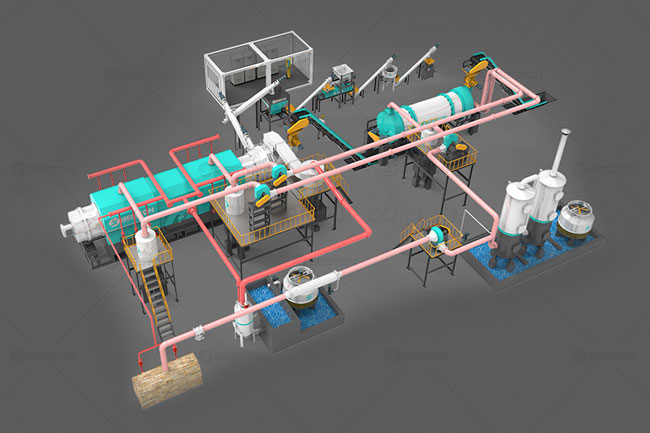

A sugarcane bagasse charcoal making machine is used to convert sugarcane bagasse into charcoal. This process is known as pyrolysis. The sugarcane bagasse is placed in the machine where it is heated to high temperatures in the absence of oxygen. This causes the sugarcane bagasse to break down into its component parts, including charcoal, gas, and oil. The resulting mixture is then cooled and the charcoal is collected. The remaining gas and oil can be used as fuel for the sugarcane bagasse charcoal making machine or sold as a by-product.

Production Process

There are 4 steps involved in making charcoal from sugarcane bagasse. They are as follows:

1. Crushing

Crushing grinds the biomass material into a small particle size that is suitable for the charring process. It is an important step in the charcoal making process because it helps to break down the lignin in the biomass, which makes it easier for the charcoal to be produced. There are two types of crushing that can be used in a sugarcane bagasse charcoal making machine: dry crushing and wet crushing. Dry crushing is more effective at breaking down the lignin, but it can also produce more dust and fines. Wet crushing is less effective at breaking down the lignin, but it produces less dust and fines. View the case right now: https://bestonmachinery.com/charcoal-making-machine-in-ghana/.

2. Drying

Drying reduces the moisture content of the material before it enters the pyrolysis reactor. This is important because the presence of water will inhibit the reaction and reduce the yield of charcoal. The material must be dried to a moisture content of less than 10% before it can be used in the reactor. There are several methods that can be used to dry the material, including sun drying, kiln drying, and oven drying. The most effective method will depend on the type and size of the material, as well as the available resources.

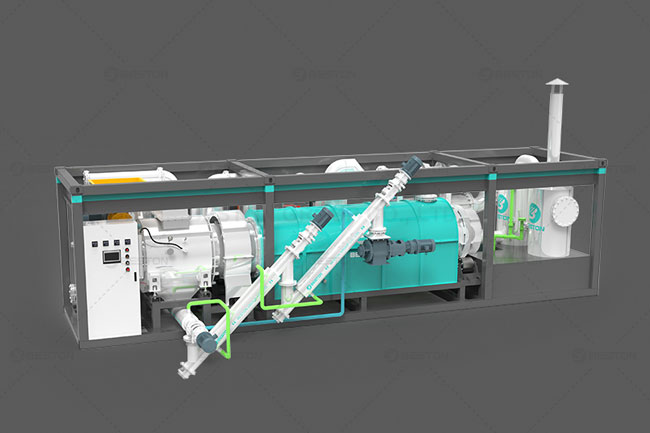

3. Briquetting

Briquetting is the process of compressing shredded material into briquettes (small, uniform shapes) under high pressure. It increases the material’s density, making it ideal for use in a sugarcane bagasse charcoal making machine. Sugar cane bagasse is a common type of biomass that can be briquetted. In a sugarcane bagasse charcoal making machine, the biomass is first dried and then fed into a briquetting machine, where it is compressed at high pressure. The resulting briquettes are then fed into a carbonization furnace, where they are heated to high temperatures in the absence of oxygen. This process transforms the biomass into charcoal, which can be used for a variety of purposes.

4. Carbonizing

Carbonizing, also known as pyrolysis, is a key step in the production of charcoal. During carbonizing, the temperature of the wood is raised to high levels in the absence of oxygen. This causes the wood to break down into its component parts, including cellulose, lignin, and hemicellulose. The resulting charcoal is more porous and has a higher surface area than raw wood, making it ideal for use in a wood pyrolysis machine.

Charcoal briquettes are a popular choice for cooking, and while there are many different brands available on the market, most of them use similar ingredients. By making your own charcoal briquettes from sugarcane bagasse, you can save money and ensure that you know exactly what is going into them.