Are you in the market for a new charcoal kiln? If so, there are a few features you’ll want to keep in mind when making your purchase. In this blog post, we’ll outline the must-have features of a charcoal furnace. So, whether you’re a seasoned pro or just starting out, read on to learn more!

Understanding how a charcoal kiln works

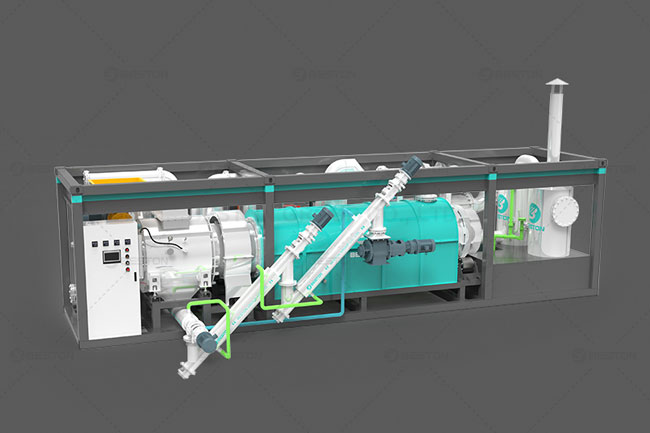

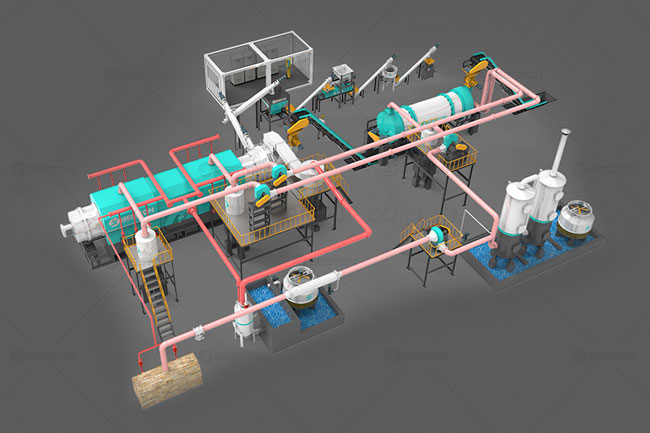

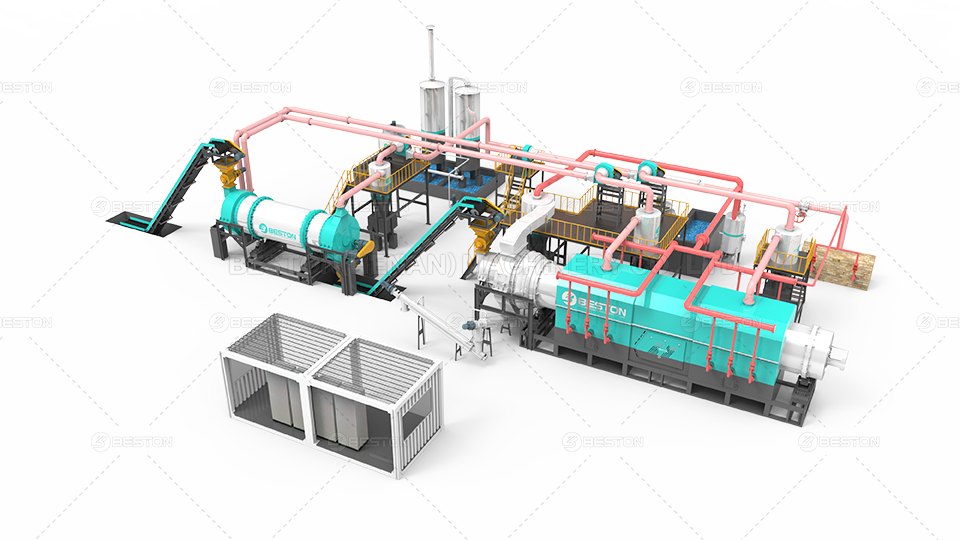

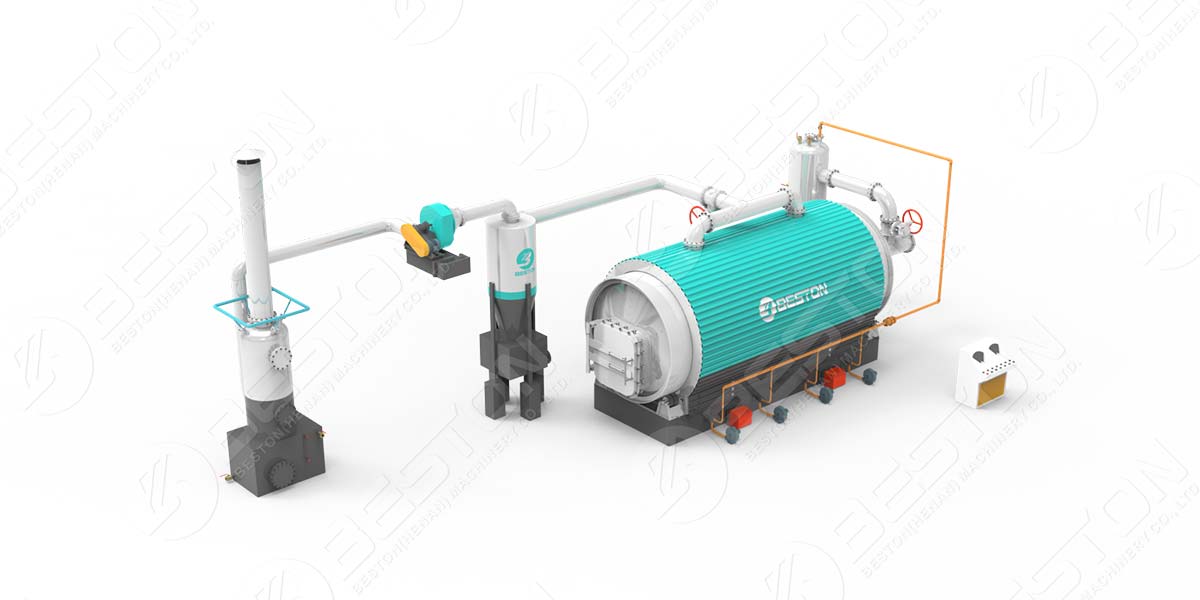

A charcoal kiln is a type of oven that is used to produce charcoal. The process of making charcoal in a kiln is known as carbonization. Charcoal kilns come in a variety of sizes and shapes, but the most common type is a rectangular structure with a metal roof. The inside of the kiln is lined with firebrick, and there is a stack of wood logs at one end.

To make charcoal, the logs are placed in the charcoal maker for sale and then set on fire. The resulting smoke and gases are channeled out through a flue, leaving behind a layer of charred wood. The process of carbonization can take anywhere from several hours to several days, depending on the size of the kiln and the type of wood being carbonized. Once the carbonization process is complete, the charcoal is allowed to cool before being removed from the kiln.

Applications of a charcoal kiln

Charcoal has a wide range of uses, both industrial and domestic. It is an essential ingredient in the production of iron and steel, as well as other metals such as aluminum and copper. In addition, it is widely used as a fuel for barbecues and grills. As charcoal burns at a higher temperature than wood, it can be used to achieve a searing heat that is ideal for cooking meat. Charcoal briquettes are also commonly used in home heating appliances such as wood stoves and fireplaces. Lastly, charcoal is sometimes used as an absorbent material in water filtration systems.

Fin more applications of charcoal kiln: https://bestonasia.com/coconut-shell-charcoal-making-machine/.

Features When Purchasing a Charcoal Kiln

When purchasing a charcoal kiln, there are several features you should look for to ensure that you are getting a high-quality product. The first is a good seal. A kiln that doesn’t seal properly will allow air to enter, which can result in incomplete combustion and lower yields.

An adjustable draft door is also a feature you shouldn’t miss. This feature allows you to control the amount of air flow, which is critical for regulating the temperature inside the kiln. Finally, look for a kiln that comes with a thermometer. This will allow you to monitor the temperature inside the kiln so that you can adjust the airflow as needed. By taking these factors into account, you can be sure that you purchase a biomass pyrolysis plant that meets your needs.

As you can see, there are a few must-have features of a charcoal kiln for sale. Be sure to keep these in mind when making your purchase, and you’ll be sure to get a high-quality product that meets your needs. Also, remember to compare the models from different manufacturers to get a better idea of how much to spend.