Tyre pyrolysis has become one of the most lucrative investments in the recent past. Waste tyres are non-biodegradable, and their production is in large volumes. As such, they pose a significant challenge when it comes to disposing of them. This technology has made it easier to get rid of the tyres, and at the same time releasing useful substances. If you are looking for quality tyre pyrolysis plant, you need to find top tyre pyrolysis plant manufacturers first.

Explanation of Tyre Pyrolysis

The chemical process of turning waste tyres into useful substances is called pyrolysis. In the process, the high molecular weight substances are broken down into low molecular weight compound. The method employs the use of high temperatures and a suitable catalyst. Tyre pyrolysis (also called tire-to-oil), converts the waste tyre into carbon black, fuel oil, steel wires, and combustible gas.

With the technology, a tyre gives 45-50% oil, 12 % steel, 30-35 % carbon black, and 8% combustible gas. Tyre pyrolysis plant manufacturers create the reactors with precision to ensure they give the desired results. It is important to note that different material has different levels of oil.

Simplified Tire Pyrolysis Process

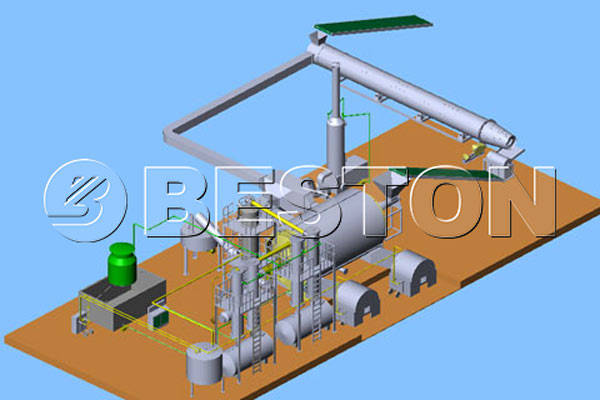

The process starts by feeding the tyre into the pyrolysis reactor. This process is either manual or automatic using an auto-feeder and then heat. To heat, you can use coal, fuel gas, charcoal, wood, etc. The reactor heats slowly until the required temperature (250 degrees centigrade) where the oil gas will start to form. The oil gas is then condensed within the condensation chamber into oil. To increase the efficiency of the system, the gas that can’t be condensed is sent back to the combustion chamber as fuel. After completing the process, let the reactor cool to 40 degree Celsius. Remove the carbon and the steel wires either manually or automatically depending on the system. The yield is 45% oil, but with advanced technology, this level can reach 50%. Majority of the system use the batch type process. In this system, you feed the raw material on one side and let the process run to completion. Cool the machine, discharge the carbon, wires, and oil before starting the second process.

Why Choose Top Tyre Pyrolysis Plant Manufacturers?

Many people are embracing this green technology. Therefore, numerous companies are building reactors and installing them for their customers. As a profitable investment, tyre pyrolysis plant manufacturers strive to produce high-quality machines for greater efficiency.

While buying, look at features like sturdy construction, corrosion resistance, High flexibility, and low maintenance. To enhance green technology and sustainability, having a machine that is geared towards protecting the environment, cost-effective, energy saving and has a higher fuel output is an excellent option. The tyre to oil plant cost is high, but you can also get high returns.

Since technology is advancing, manufacturers work round the clock to produce the best machines. This way the customers can select those that fit their specific needs. A pyrolysis reactor can be categorized into a fully continuous pyrolysis reactor, batch type, and the semi-automatic type groups. And the quality one can supply:

An efficient system employs;

The use of an air heating technology in the heating system as a measure to improve safety and heating efficiency;

There is neither production of smoke nor smell, a property geared towards environmental protection;

Feeding a whole tyre in the system, this eliminates the need to break it down into smaller pieces. This property saves on labor cost and time.

Why Need Tyre Pyrolysis Plant Manufacturers Services

No one can deny the fact that tyre recycling is helpful to society and the environment in equal measures. Accumulation of tyres (black pollution) is not only an eyesore but significant source of harm to the environment. Therefore, reactors from these manufacturers are essential in;

Getting rid of the accumulating rubber and tyres; When breaking down the tyres, you get useful substances including tyre oil, steel wire, carbon black, and combustible gas. These products can be put into various uses.

Also, the manufacturers can customize your plant according to your specification, and they will install it, and repair it if the need arises. Before installation, the manufacturers will carry inspections to assess the suitability of the reactors in your space. Welcome to contact Beston Machinery for more details.