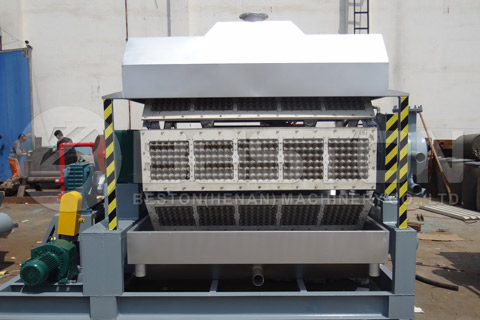

When you are considering the egg tray manufacturing business (бизнес по производству лотков для яиц) as something that you would like to do, you will find that you can make a great living at this. It is a business that will remain good as long as people continue to eat eggs and they will. It is relatively easy to set up a business like this one and you can make a lot of profits in a short amount of time. It is also eco-friendly and this bodes well in a society that is always worried about the protection of the environment. This is a business that will do just that.

The Egg Tray Manufacturing Business

When you want to set up a business like this one, you will need to develop a business plan. You want to be as organized as possible so that you can make money right from the beginning. Since this is what you need to do, here are some tips to get you started:

1. Competitors

You want to know who your competitors are. Make sure that you seek them out so that you know what they are pricing their egg trays at so that you don’t price yourself out of the competition. Which pulp molding suppliers do they deal with when they are operating? You need to know all sorts of information about them and how they are operating.

2. Target Market

Make sure that you have a target market in mind. You want to designate who you are going to sell your egg trays to. Starting out, you will probably just want to target small stores. Once you get moving in your business more, you can move on to the larger businesses.

3. Money

Make a budget on the money you need to get started in your business. Comparison shop for prices for egg tray machines(цена оборудование для лотков для яиц). Know how much money you will need to invest in your new business.

4. Marketing Your Product

You will want to begin a marketing plan for your product. You can advertise in your local newspaper. The best marketing plans are completed online. You want to have a great website that will lure customers your way. Make sure that it is set up properly and that you use SEO to entice your target market to visit your website and purchase your egg trays.

Once you get up and running, you will see that this is a business that will continue to give you the profits that you desire. There are many people that love eggs and as long as they still do, you will stay in business with your egg trays. That is because this type of business never ends and you will have a constant stream of income when you decide that you want to get into it. Be sure that you focus and concentrate on the things that you need to do on a daily basis so that you can make your new company a huge success now and well into the future. Click www.Bestongroup.ru/ to find what you need.