In a world dominated by convenience, the ubiquity of plastic has become both a boon and a bane. While it has revolutionized various industries with its versatility, the environmental repercussions are undeniable. Individuals, however, hold the power to make a significant impact by consciously minimizing their plastic footprint in daily life.

Understanding the Plastic Predicament

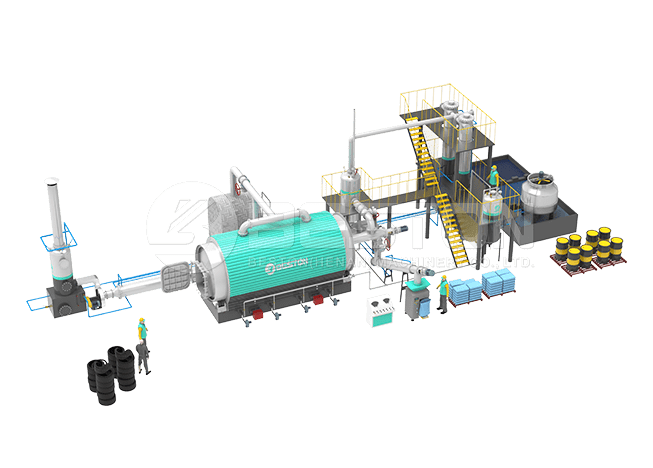

To embark on a journey towards a greener lifestyle, it’s crucial to comprehend the intricacies of the plastic predicament. Plastic, a synthetic polymer derived from petrochemicals, is renowned for its durability and malleability. Yet, this very durability poses a grave threat to our ecosystems as plastic takes centuries to decompose, lingering in landfills and oceans. More information on plastic pyrolysis plant here.

Rethinking Daily Habits

-

Reevaluate Packaging Choices

Begin your eco-conscious journey by scrutinizing the packaging of products you purchase. Opt for items with minimal or biodegradable plastic packaging to reduce your environmental impact.

-

Embrace Reusable Alternatives

Say goodbye to single-use plastic by adopting reusable alternatives. Stainless steel or glass water bottles, cloth shopping bags, and metal straws are excellent substitutes that help break free from the shackles of disposable plastic.

-

Mindful Grocery Shopping

In the realm of sustainable living, every purchase matters. Consider buying in bulk to minimize packaging, and choose products stored in glass or cardboard instead of plastic containers.

-

DIY Cleaning Products

Unveil your inner alchemist and concoct your cleaning potions. This not only reduces reliance on plastic bottles but also allows you to control the ingredients, fostering a healthier home environment. The plastic oil machine is an effective machine to process plastic.

Unraveling the Mysteries of Recycling

-

Master the Art of Recycling

Recycling is a potent weapon in the war against plastic pollution. Educate yourself on the recycling codes and guidelines in your area to ensure your efforts contribute positively to the environment.

-

Creative Upcycling

Elevate recycling to an art form by indulging in creative upcycling projects. Transform discarded plastic items into functional or decorative pieces, breathing new life into what was once considered waste.

Navigating Social Challenges

-

Spread Awareness

Becoming an eco-warrior involves more than personal choices; it requires spreading awareness. Engage in conversations about the impact of plastic on the environment, encouraging others to join the cause. Check the plastic to fuel machine here.

-

Influence Your Community

Take a proactive role in your community by suggesting or participating in initiatives to reduce plastic consumption. Community gardens, recycling programs, and educational workshops can inspire lasting change.

The Future of Plastic Conscious Living

-

Support Sustainable Brands

Align your values with your purchases by supporting brands committed to sustainable practices. From clothing to household items, numerous brands are prioritizing eco-friendly alternatives over traditional plastic.

-

Continuous Learning

Sustainable living is an ever-evolving journey. Stay informed about the latest advancements in plastic alternatives, sustainable practices, and environmental policies to adapt and refine your lifestyle choices.

In conclusion, minimizing your plastic footprint is not just a lifestyle choice; it’s a commitment to preserving the planet for future generations. Through conscious choices and a collective effort, individuals can pave the way for a more sustainable and plastic-free world. See Beston Group here.