The world has increasingly turned its attention to the art of charcoal making machine production through pyrolysis. This method, rooted in the scientific conversion of organic materials into valuable charcoal, is not merely a process but a strategic initiation into a profitable endeavor.

Understanding the Basics

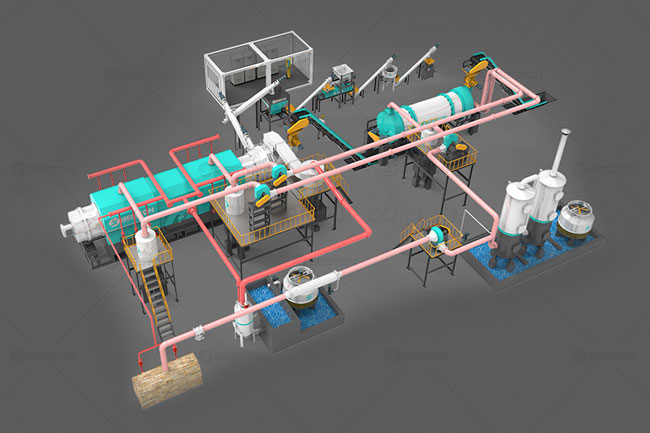

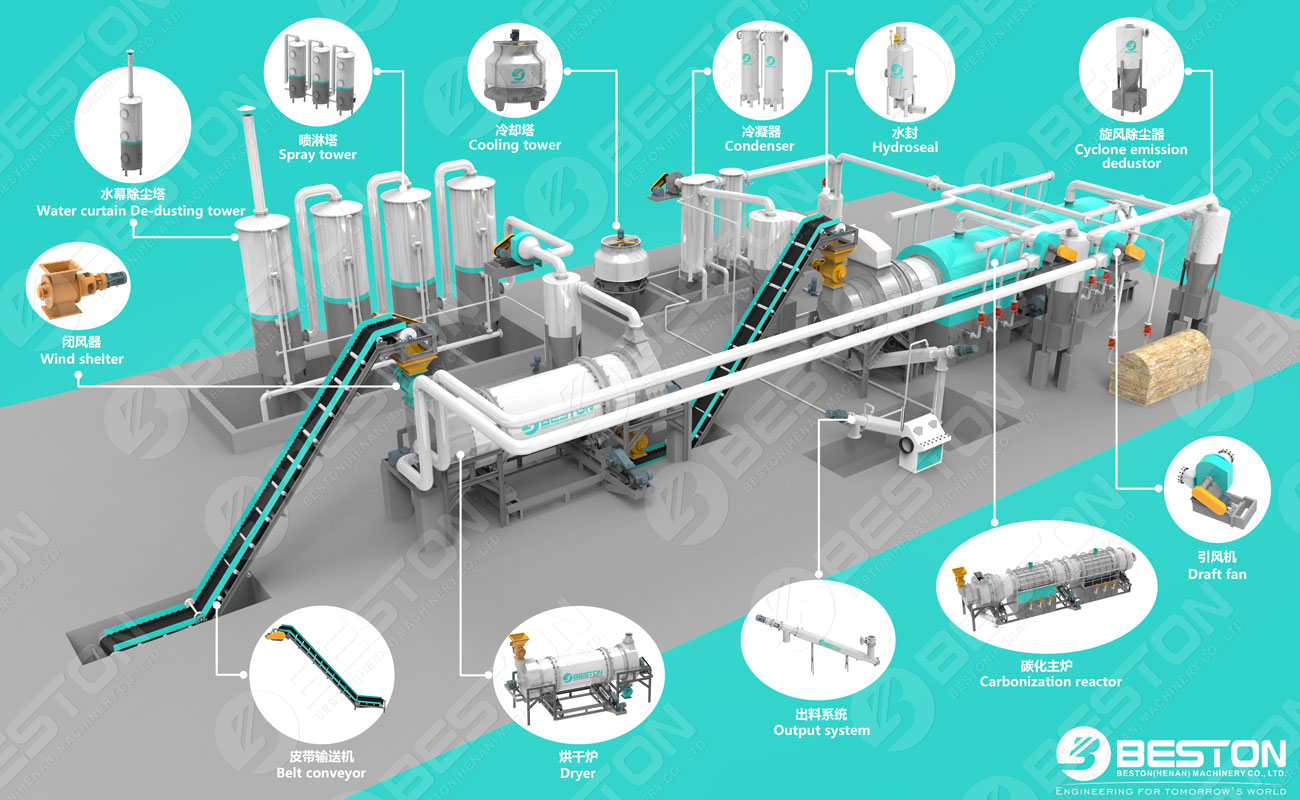

To embark on the path of profitable pyrolysis, one must grasp the fundamentals. Charcoal making machine serves as the linchpin, pivotal in transforming biomass into charcoal through the pyrolytic process. Pyrolysis, a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen, is the heart of this operation. The key is to extract charcoal while leaving behind valuable byproducts like bio-oil and syngas.

Selecting the Ideal Charcoal Making Machine

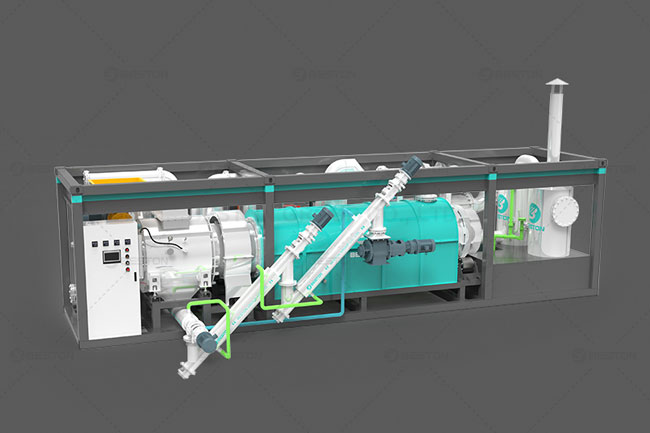

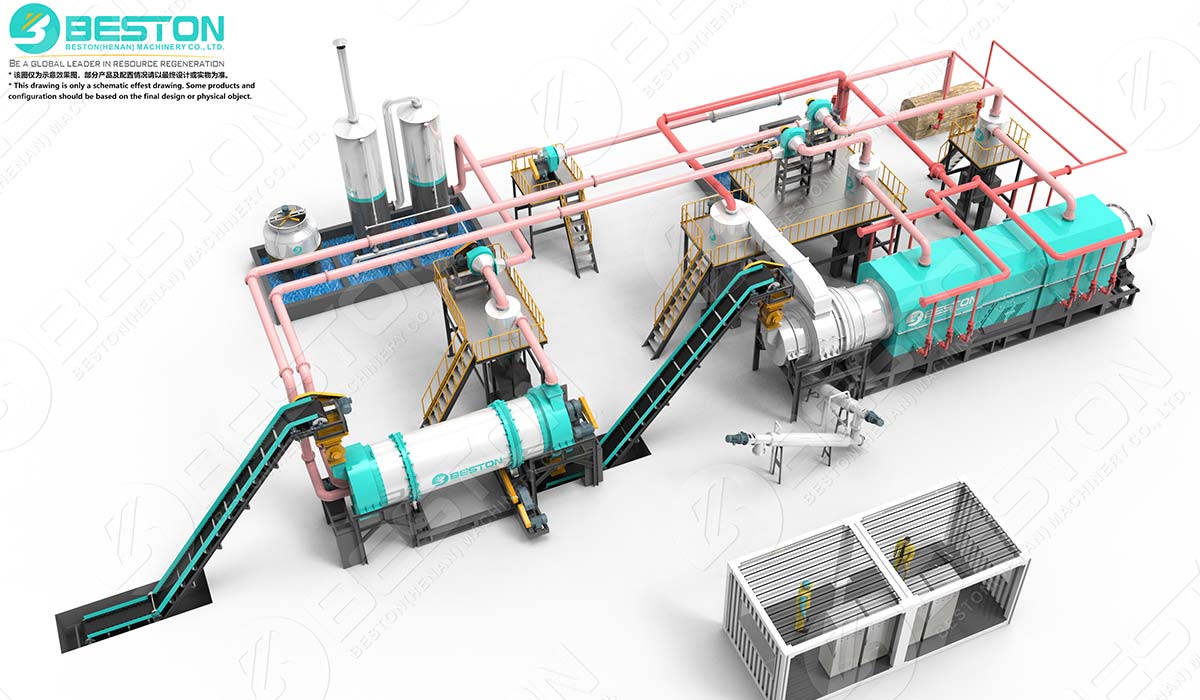

Choosing the right charcoal making machine is a critical step that demands meticulous consideration. Opt for a machine equipped with cutting-edge technologies such as a continuous pyrolysis system and an efficient condensation system. Look for features like automated control systems to streamline operations and enhance overall efficiency. A judicious selection at this stage sets the tone for a successful venture.

Locating Raw Materials

The backbone of any charcoal production project lies in the raw materials. Seek out biomass sources rich in carbon content, such as wood chips, coconut shells, or agricultural residues. Ensure a consistent and sustainable supply chain to avoid operational hiccups and maintain production momentum.

Site Selection and Regulatory Compliance

Securing the right location for your biochar production equipment is paramount. Opt for areas abundant in biomass resources and with convenient access to transportation infrastructure. Simultaneously, be cognizant of environmental regulations and zoning laws. Complying with these standards not only safeguards the ecosystem but also ensures a smooth operational trajectory.

Crafting a Business Plan

No venture can thrive without a well-crafted business plan. Outline your production capacity, market analysis, and financial projections. Factor in the initial investment for the charcoal making machine, operational costs, and potential revenue streams from charcoal and byproduct sales. A comprehensive plan serves as a roadmap, guiding your business through potential challenges.

Installation and Commissioning

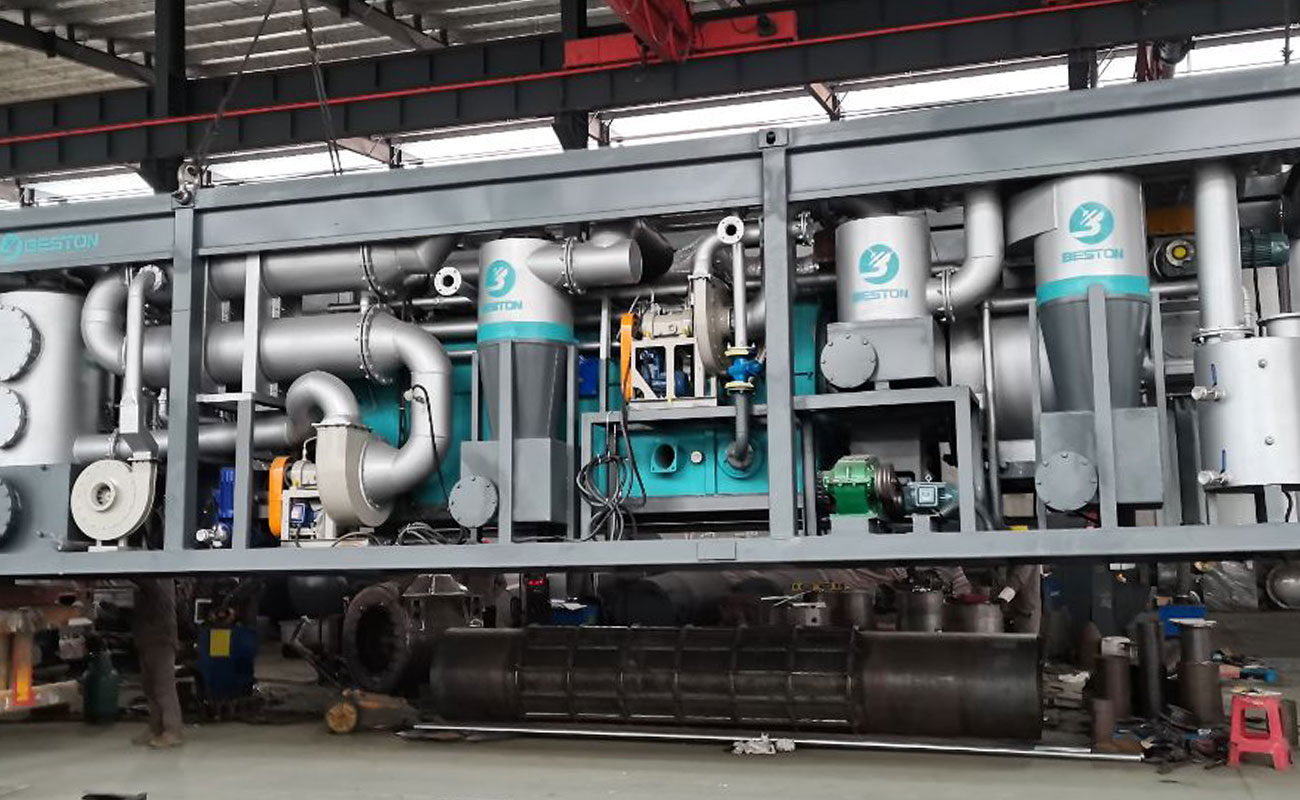

Once armed with a robust business plan, proceed to the installation and commissioning phase. Collaborate closely with the machine manufacturer to ensure a seamless integration into your production facility. Thoroughly test the equipment and establish operational protocols to guarantee a smooth workflow.

Operational Optimization

Efficiency is the bedrock of profitability. Regularly monitor and optimize your rice husk/straw/coconut shell/wood charcoal making machine operations. Implement preventive maintenance schedules, adopt technological upgrades, and train your workforce to handle the machinery adeptly. The goal is not just charcoal production but a streamlined, cost-effective process.

Marketing Your Charcoal

In a market saturated with various charcoal products, strategic marketing is imperative. Highlight the eco-friendly nature of your charcoal, emphasizing its origin from sustainable biomass sources. Explore certification programs that validate your commitment to environmental responsibility. Building a brand around the quality and sustainability of your product will distinguish it in a competitive market.

Diversification Opportunities

Beyond traditional charcoal, explore avenues for diversification. Utilize the byproducts of pyrolysis—bio-oil and syngas—as potential revenue streams. Bio-oil finds applications in industries like cosmetics and pharmaceuticals, while syngas can be harnessed for energy production. Diversification not only enhances your product portfolio but also fortifies your revenue streams.

Embracing Technological Advancements

The landscape of pyrolysis and charcoal making machines is continually evolving with technological advancements. Stay abreast of innovations in pyrolytic processes and machine design. Consider periodic upgrades to enhance efficiency, reduce emissions, and stay competitive in a dynamic market. Curious to know more? Visit Beston Group for a comprehensive look at what we have to offer.